American chemical company Milliken & Co. has announced plans for a major expansion in capacity for its Millad NX8000 clarifying agent for polypropylene at its Blacksburg, S.C., facility.

The privately owned company said April 23 at Chinaplas it will double NX8000 production and add on an additional redundant manufacturing line. Company representatives say that the expansion will be completed in 2015.

No information was given on the amount of the investment or the scale of the facility expansion, but the company described the investment its “most significant capital investment in its Millad clarifier business to date.”

“The need for a capacity expansion comes from Millad NX 8000's success as the clarifier of choice for new, transparent polypropylene applications, from food storage to personal care packaging,” said Allen Jacoby, vice president of plastics additives for Milliken in a statement.

The clarifying agent was first introduced at K Show in 2007 and has been widely adopted by brand name manufacturers such as Tupperware and Ikea.

Cristina Acevedo, global product line manager for Milliken’s plastic additives business, who spoke to Plastics News at ChinaPlas in Shanghai, said that demand has been hot for NX 8000 because it can replace high-density resins like polycarbonate, polystyrene, and PET with lower-density polypropylene.

This is desirable because it can make plastic even more clear, and because it uses less energy — a reported decrease of 13 percent — and costs less. The additive is microwaveable, recyclable, and bisphenol A free. Acevedo said that globally 70 percent of the market for clear PP is now using NX8000 compared to traditionally used clarifiers.

“It’s doing really well in Asia,” she said. “All the PP producers want NX8000.”

Milliken overall is growing strongly in Asia, said Wim Van de Velde, director of marketing for the plastic additives group.

“Right now, Asia is our biggest region,” he said. “Traditionally it is a third of our business, but now it is half.”

Looking forward, the company is focusing on polyethylene and PP development.

“They don’t have any regulatory issues,” he explained, adding that they are low cost and low density. “We don’t see any black clouds [over them]. That’s our current judgment, time will tell.”

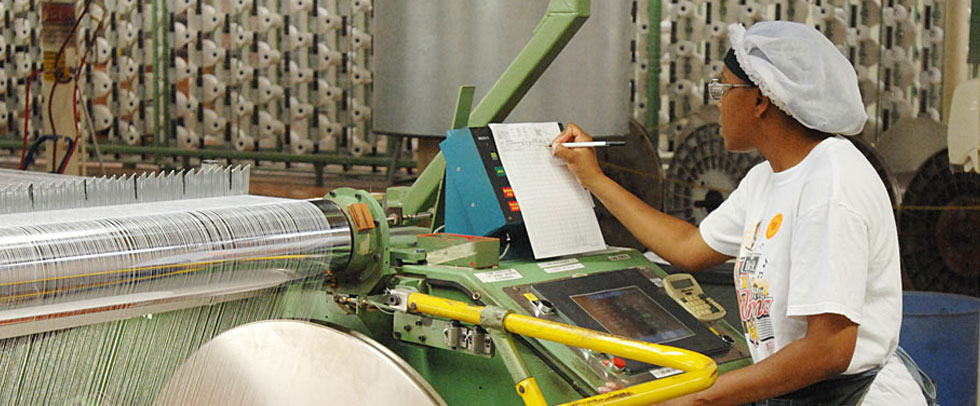

Milliken ranks as one of the world’s largest privately held chemicals and textiles makers, with annual sales estimated at more than $3 billion. With headquarters in Spartanburg, S.C., the company has Asian offices in Shanghai, India and Singapore.

While their ChinaPlas booth showcased their successes with NX8000 and its Hyperform HPR reinforcing agent, a Milliken executive hinted at an upcoming launch this year of a yet to be named additive.

Reed Walker, global marketing and business development manager for Milliken’s plastics additives group said the company is developing an additive that gives a whole new set of properties to

polyethylene. The additive is a polyethylene nucleating agent being developed for the HD market.

”It gives a different kind of crystallization effect in polyethylene that should open up a whole new market for us,” he said. “It’s almost as if it is a completely new material.”

He said the additive has thermal, stiffness and shrinking properties that make it desirable. He speculated that it could potentially allow polyethylene to compete in places traditionally owned by PP, such as pallets, storage boxes, totes, trash cans and automotive.

“It becomes potentially a game changer. We’re in the learning phase,” he said, adding that the company expects to launch the additive late this year.

Courtesy: Plastic News

| Copper Scrap View All | |

| Alternator | 0.40 (0) |

| #1 Copper Bare Bright | 4.07 (0.02) |

| Aluminum Scrap View All | |

| 356 Aluminum Wheels (Clean) | 0.77 (0.01) |

| 6061 Extrusions | 0.67 (0.01) |

| Steel Scrap View All | |

| #1 Bundle | 360.00 (0) |

| #1 Busheling | 380.00 (0) |

| Electronics Scrap View All | |