Characteristics

Aluminum plate is used as a raw material for parts as diverse as automotive side panels, storage tank walls, architectural panels and signs. The versatile properties of aluminum ensure high performance, durability and long life for the end products. AL 3003 is an alloy with very good corrosion resistance and moderate strength. It is not heat treatable and develops strengthening from cold working only. These include: High strength, Low weight, Excellent corrosion resistance, Temperature resistance, including excellent performance at temperature extremes, Thermal conductivity, Ease of machining, stamping, forming and welding.

3003-H14 Aluminum Plate - (ASTM B209, QQ-A-250/2) Excellent weldability, formability, with good corrosion resistance make 3003 Aluminum Plate a popular and economical choice. 3003 Aluminum Plate has a smooth, shiny finish and is popular for many cosmetic and industrial applications.

3003 Aluminum is alloyed with 1.20% manganese, which increases the strength of 3003 over commercially pure aluminum (1100 series). 3003 has excellent workability, weldability, and good corrosion resistance. It is used for drawing, forming, spinning, fuel tanks, sheet metal works and other applications that require moderate strength for an aluminum with good weldability. H14 designates the temper, and means that 3003 has been strain hardened and partially annealed. In this condition, 3003 can be easily formed. Embossing or debossing 3003 in this temper should not strain or crack the aluminum. Â 3003 ALUMINUM TREAD PLATE - Often referred to as diamond plate, it has the same properties of 3003-H14, while excellent at resisting corrosion, and strong for light weight aluminum applications. The diamond trend pattern is slip-resistant and cosmetically appealing.

3003 aluminum plate exhibits moderate strength and very good corrosion resistance. 3003 aluminum tends to be gummy when machined, requiring special handling. The material may show slight discoloration when anodized, but it reacts well to mechanical and organic finishings. It is easily welded and brazed, but soldering is limited to the torch method.

Applications

3003 aluminum plate is mainly used to manufacture stamped parts that require moderate strength and low weight. These include food and chemical handling equipment, appliance components, truck and trailer roofing, heat exchangers, pipe jacketing, hardware, walk ways and catwalks, floor panels and wall panels, lawn furniture components, cooking utensils, builders hardware, storage tanks, mail boxes, cabinets, fan blades, awnings, siding, kitchen equipment, decorative trim, architectural uses, signage applications, etc. Where greater strength is required, consider 5052-H32. 3003 plate is mainly used for manufactured stamped parts because of its light weight and moderate strength.

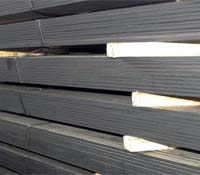

3003-H14 Aluminum Plate Pictures