Circuit board recycling machine is combined with the domestic and international advanced technology was developed. The equipment adopts the advanced physics law recovery processes; purity and separation rate of equipment is the highest in the all of the waste circuit board recycling equipment.

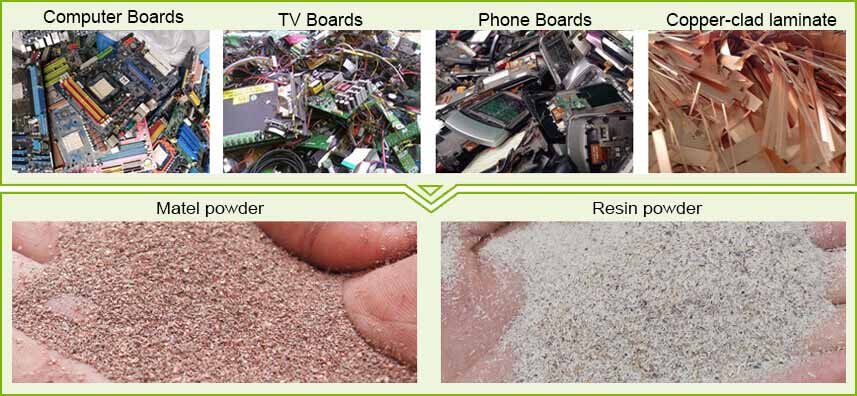

Circuit board recycling machine can help you get metals, resin powder and fiber powder from used Printed Circuit boards. Such as, waste computer boards, waste cell phone boards, waste TV boards, pcb scrap etc.

Because of the high value of the metals, fiber and resin, there is no doubt that this series plants not only help to change waste to treasure, but also bring great economic benefits.Through years of practice and theoretical analysis, we obtain the best separation result, the separating purity can be reached to 99%.

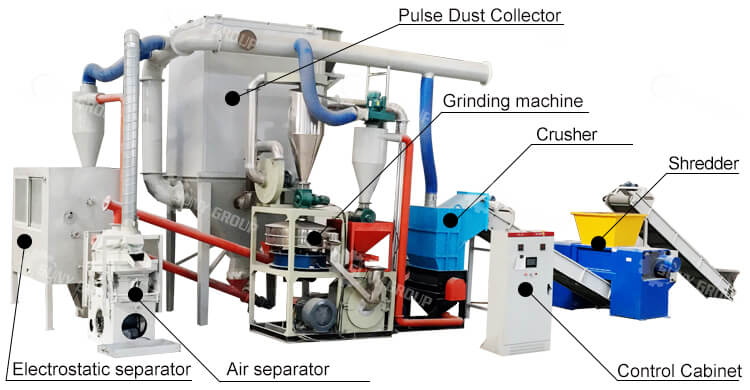

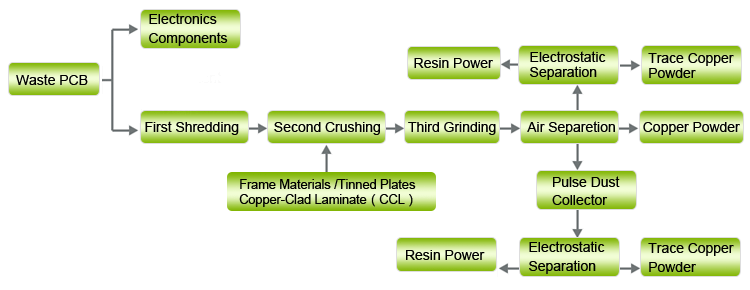

First, the circuit will be separated into motherboards and some circuit components .Because of its special characteristic.the boards need the dry-type grinding and separating system .These boards are grinder into mixture power f the metal and resin fiber .Then .the mixture will be separating via air flow system the separating rate can be up to 97%. Finally .the rest mixture are processing via special electrostatic separator .the machine can achieve the 99% separating rate. Apart from that .the mesh also can be collected by the pulse dust collector .which guarantee 99% collecting rate.

Raw materials that pcb recycling machine can process:

1. Waste printed circuit board with or without electronic components;

2. CCL( copper-clad plate), PCB leftover material;

3. Scrap circuit boards, such as computer board, mobile phone board, TV board, etc.

waste circuit boards mainly comes from all kinds of scrap electric appliances, mainly including green board and yellow board. Green board is dismantled from waste televisions, computers, communications equipment, with high vafue;yellow palte mainly from the tape recorder, audio equipment, washing machines, air conditioning and dismantling, with low value.

I. With compact structure, reasonable layout, stable performance, low noise; Easy to replace wearing parts;

2. Coordinate operation and even feeding with PLC in the whole line;

3. Large capacity to 1000kg/h via 3-stage-crusher; Grinder with water cooling grinding;

4. Air flow separator with the separator rate over 99%; The efficiency of impulse dust collection reached up to 99%; Finer and more efficient separation via high voltage electronic separator; Effectively controlling the loss of non-ferrous metals.

Contact Us:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email:sunymachine@gmail.com

WhatsApp:+86 13674945231

Web:https://www.sunygroup.cn/

Member

Member