19W4 Steel Bar Grating

Characteristics

Steel Bar Grating, also known as Welded Steel Bar Grate is extremely strong and durable for all load bearing applications and is primarily used for pedestrian and light vehicle traffic.It is the most common available on the market and is manufactured by a resistance-weld process. It does not exhibit good corrosion resistance, so should not be used in applications that are exposed to corrosive elements. The grating selection is based on load requirement, corrosion resistance, durability, and cost. Crossbars are fused to bearing bars to form a permanent joint. They are economical, yet durable for most applications. Carbon steel grating is a heavy duty grating.Steel bar grating is available in a variety of bearing bar spacing and thicknesses depending on applications and load requirements. Available in either smooth top or serrated for slip resistance.

- Specifications: 19W4, Carbon Steel, Painted Black

- Applications: Walkways, flooring, ramps, bridge flooring, trench and drainage covers, mezzanines, platforms, stair treads, etc.

- Workability: Easy to Weld, Cut, Form and Machine

- Mechanical Properties: Tensile = 58,000 +/-, Yield = 42,000 +/-

Carbon steel grating types available are:

- Welded – The carbon steel bars are resistance welded to create a rugged, one piece constructed panel. This is the most popular of all grating types due to its strength, cost effective production, and ease of installation.

- Press Locked – Press-Locked grating is manufactured using hydraulic pressure to lock notched bars together. It provides excellent lateral support and has a clean, smooth look. It is not able to support the weight of rolling loads.

- Close Mesh – Close mesh grating has a tighter mesh than welded or press-locked grating. The bars are closer together, providing a narrower opening in the grate. It is suitable for applications requiring narrow spacing for aesthetic or functional reasons.

- Stair Tread – Welded steel stair treads are most widely used for their strength and ease of installation and are universally used in most industrial and commercial applications.

SURFACE OPTIONS AVAILABLE:

- Serrated

- Grit

- Painted

Applications:

Used in applications that require strength and is typically used for platforms and walkways in chemical plants, oil rigs, and paper mills. In addition to flooring, bar grating can be used to make drainage ditch covers, catwalks, stairway platforms and stair treads, ground mats and transformer pit covers for the electrical substation industry; trench grating covers for the automotive industry; walkways for aggregate conveyor systems; wet drainage applications at poultry plants and wastewater facilities. It is also used where open flooring is needed for air, light and heat transmission.

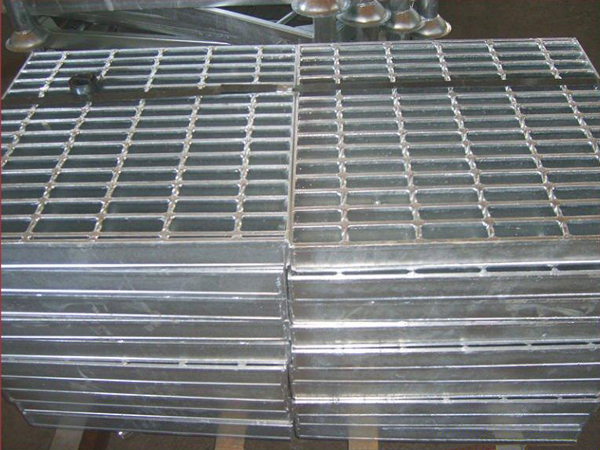

Steel Bar Grating Pictures